- All Cutting Tools

- (TA)0 degree Turning

- (T)10 degree Turning

- (UT)21 degree Turning

- (U)47 degree Turning

- (UQ)50 degree Turning

- (G)Grooving

- (GQ)Round Grooving

- (i)Threading

- (D)Face Grooving

- (DQ)Round Face Grooving

- (V)Camshaft Grooving

- (B)Back Turning

- (H)Through Coolant T

- (H)Through Coolant UQ

- (DC)Double Cutting Edge

- (S)Customized Tools

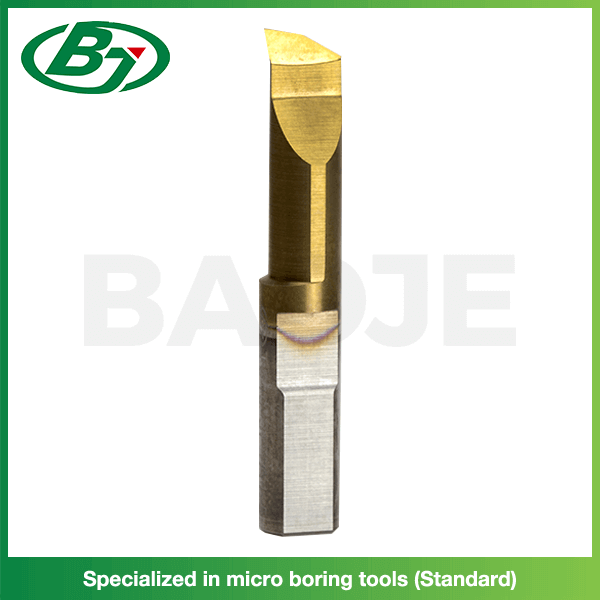

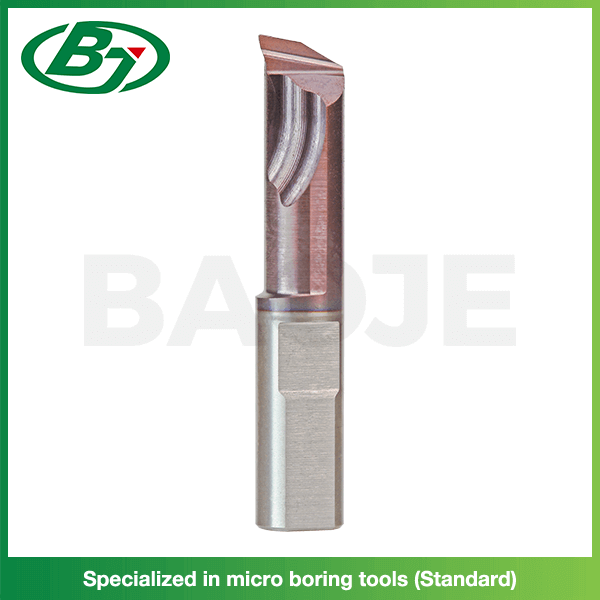

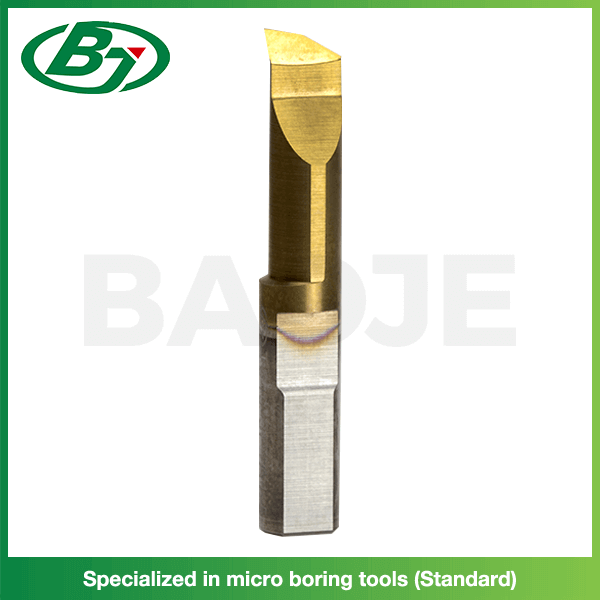

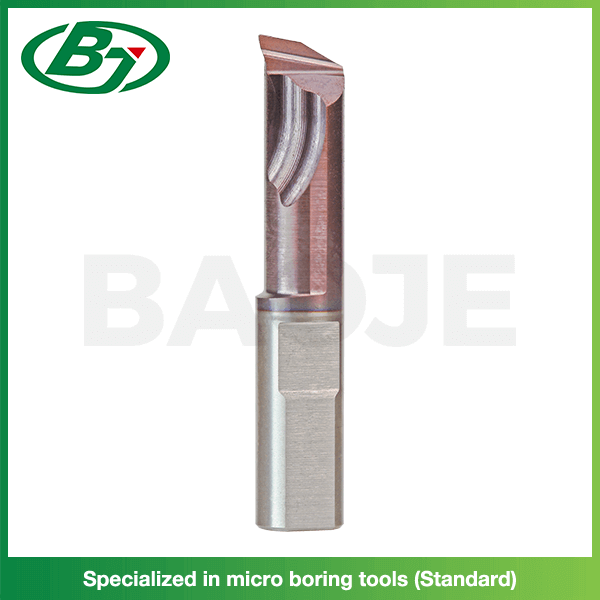

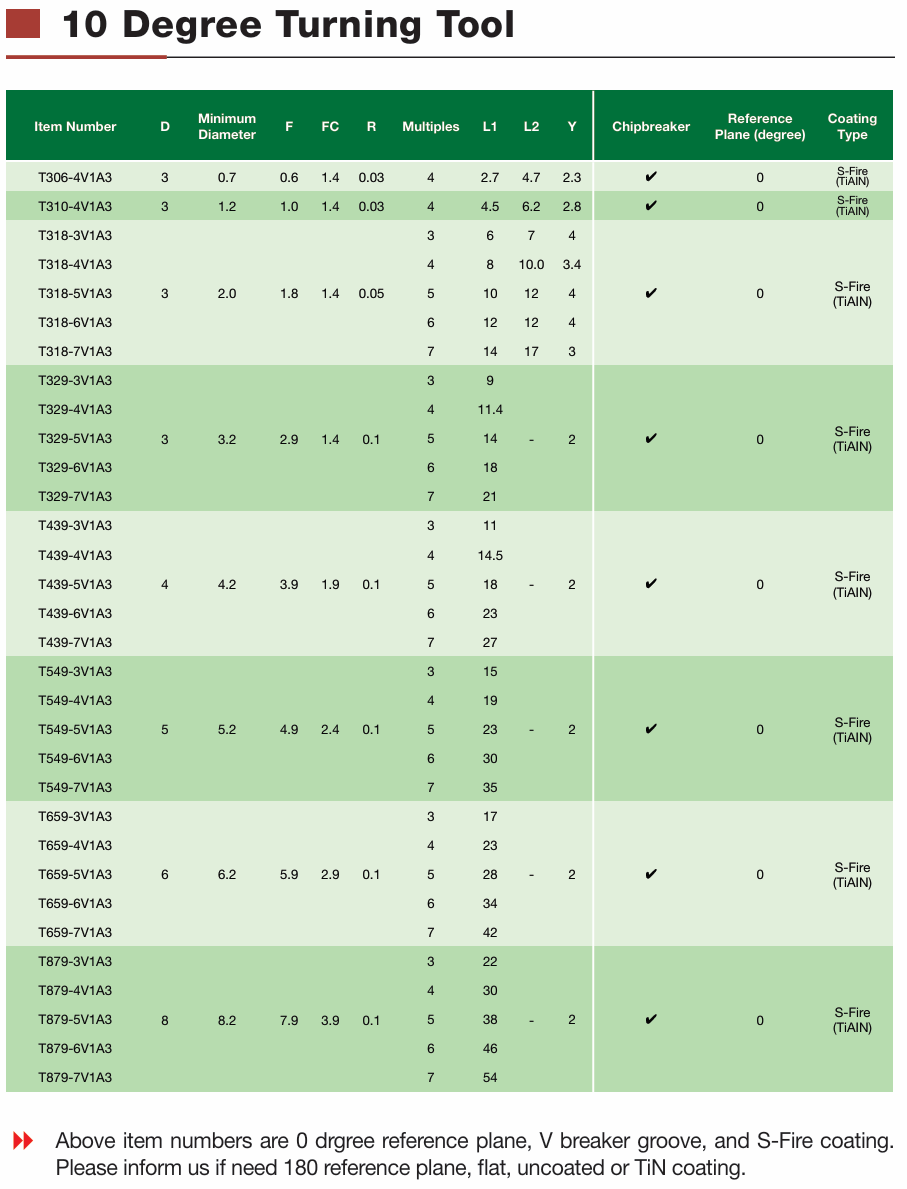

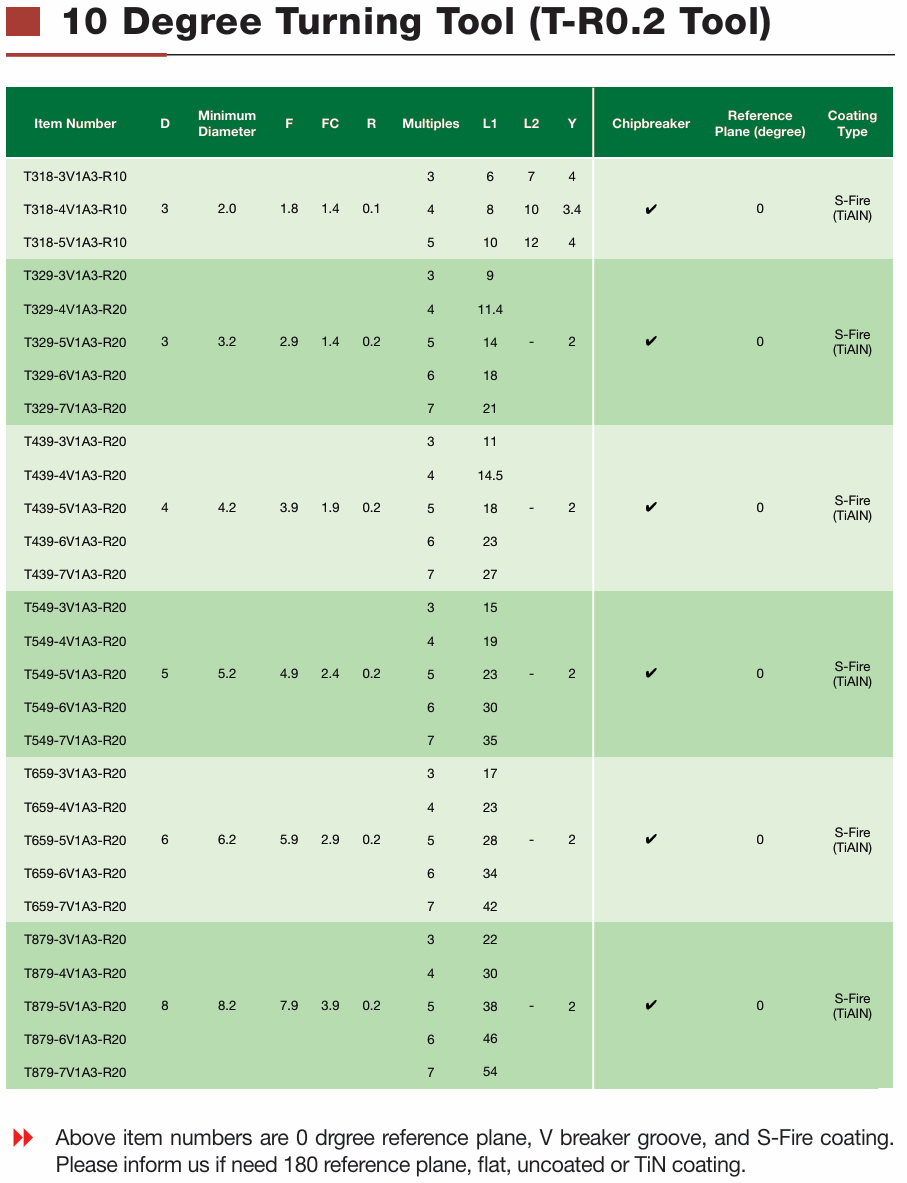

(T)10 degree Turning Tool

Specifications:

0.6mm~8mm.Tungsten carbide materials are imported from Europe and Japan.

Characteristics:

For Rough orPrecision cutting.

Notes:

Coated by imported equipment.

10 degree Turning tool specifications

Tungsten Carbide Boring 10 degree Turning Tool

Tungsten Carbide inner hole front turning tool is also named tungsten inner hole front turningt tool and is known as Turning Tool, can be used as roughing and finishing cutting, the turning tool life will be affected with workpiece material type, cutting procedure, working temperature and CNC lathe specification

CNC boring tool is divided into boring inserts and boring bars; the inserts are assembled with only one piece of screw in the inserts center section, when change the inserts, need to remove the screw completely, then remove the damaged insert to replace new insert, then to tighten the screw back to place, the toolholder with inserts is inserted into the workpiece during the machining process, inserts are divided to positive angle, negative angle and two, three and four cutting edges, CNC inner hole inserts are commonly cheaper compare to other types cutting tools.

CNC Tungsten Carbide bar sysmatic turning tools are tightened on the side with two screws, no need to take two screws out when replacing new bar, and no need to take the toolholder out of CNC lathe, only the bar is inserted into the workpiece during machining process.

CNC Tungsten Carbide non-systematic bar cutting tools need to be tightened by ER collet, tighten method is via ER collet holding tool, need to take the ER collet out from CNC lathe to change the tool.

How to use Baoje Tungsten Carbide 10 degree Turning Tool

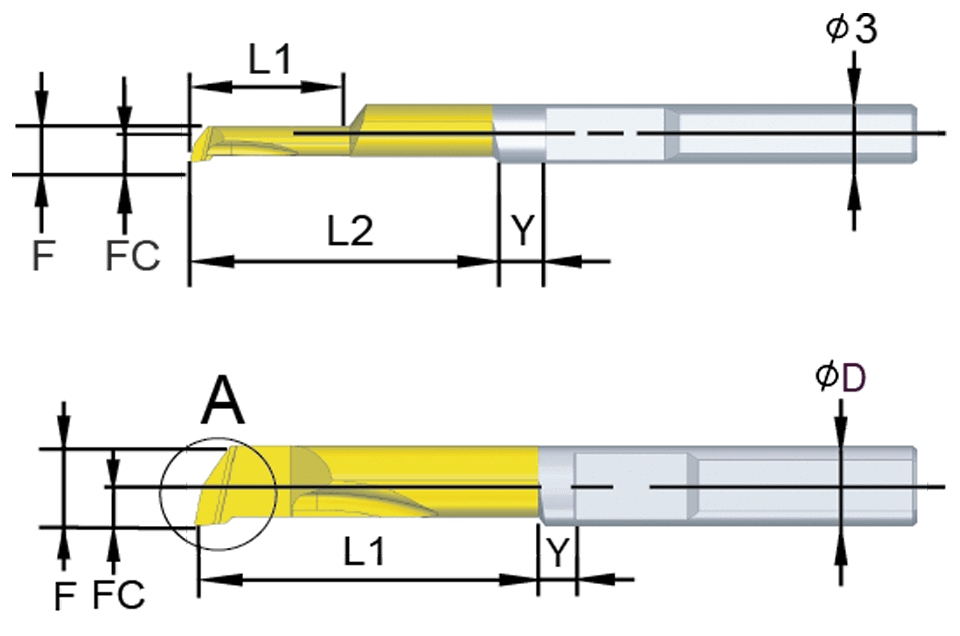

Baoje Tungsten Carbide 10 degree Turning Tool specializes micro boring purposes and we have standardized turning tools and customized turning tools, we normally provide in tungsten carbide shafts in Φ3 /Φ4 / Φ5 / Φ6 and we do customize Φ8 shaft when is necessary and required, all these tools can turn workpiece with hole diameter within: Φ10 and/or below

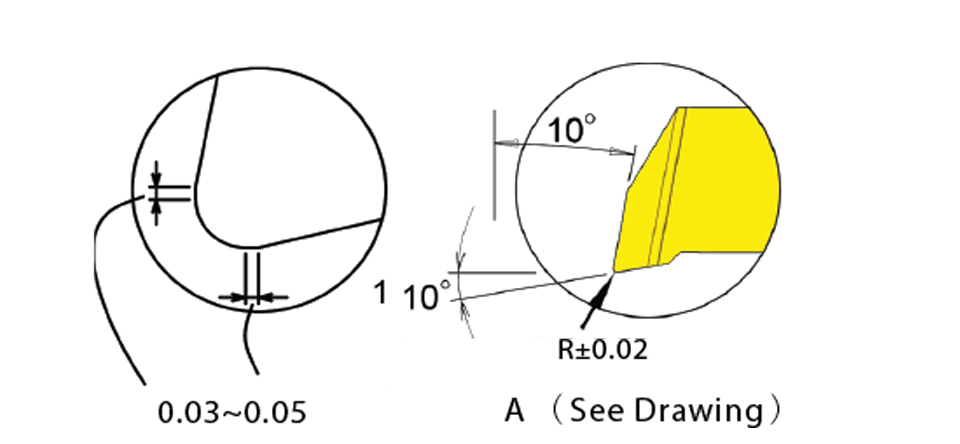

The Baoje Tungsten Carbide 10 degree Turning Tool advantage is beside standardized systematic turning tools, we can customize different cutting edge chipbreaker type according to workpiece material designation, our chipbreaker types are: breaker groove type, flat type and diamond groove type.

We will suggest customer to use flat type when the workpiece material is copper, aluminum, SUS 303 and free cutting material like 12L14, 12L15,

There two types of SUS303: 303cu is with copper, 303L is normal free cutting material with lead which is easy machining but also wears quickly so when use flat type, the tool life will be better.

If workpiece material are S15C, S45C, SUS304, SUS310, SUS316, SUS420, SUS415, SCM435 and SKD11 can use breaker groove type, these stainless steel are with higher nickel percentage and are not easy rusted, SCM is hard to machining material.

We do customize the above tool every dimensions including F / FC / L1 / L2 / ΦD / Tip Radius / Front angle, according to your requirement beside standard 10 degree turning tool.

Videos

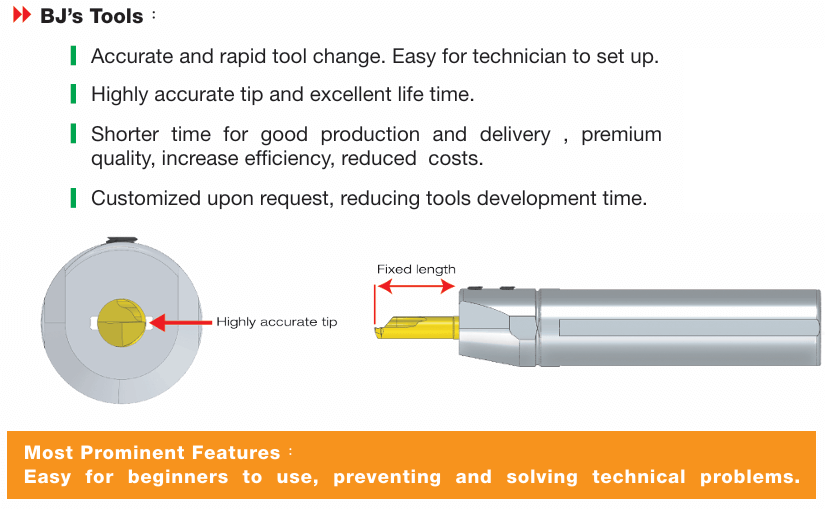

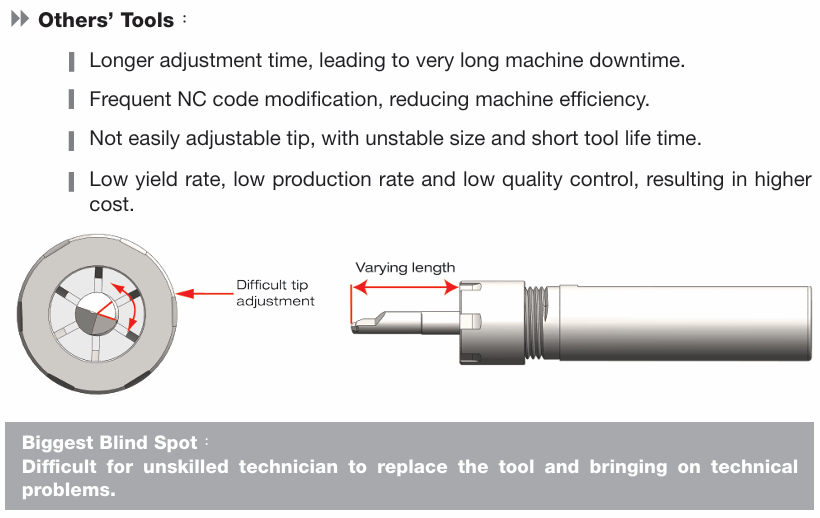

Superior techniques, premium quality adherence.

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.

Superior techniques, premium quality adherence.

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.