- All Cutting Tools

- (TA)0 degree Turning

- (T)10 degree Turning

- (UT)21 degree Turning

- (U)47 degree Turning

- (UQ)50 degree Turning

- (G)Grooving

- (GQ)Round Grooving

- (i)Threading

- (D)Face Grooving

- (DQ)Round Face Grooving

- (V)Camshaft Grooving

- (B)Back Turning

- (H)Through Coolant T

- (H)Through Coolant UQ

- (DC)Double Cutting Edge

- (S)Customized Tools

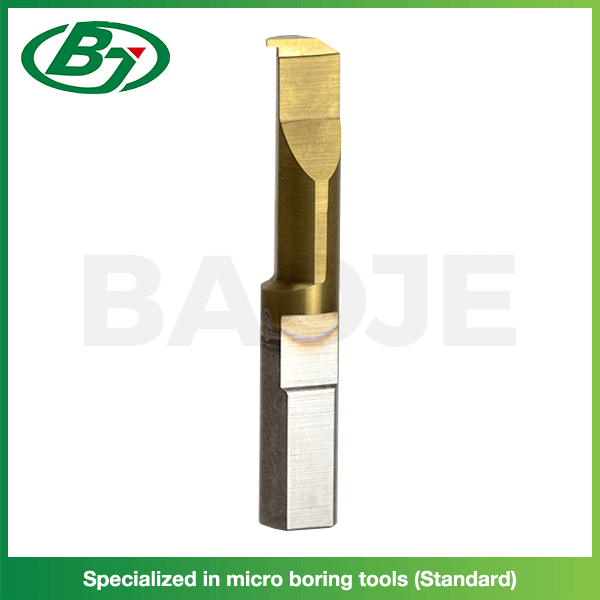

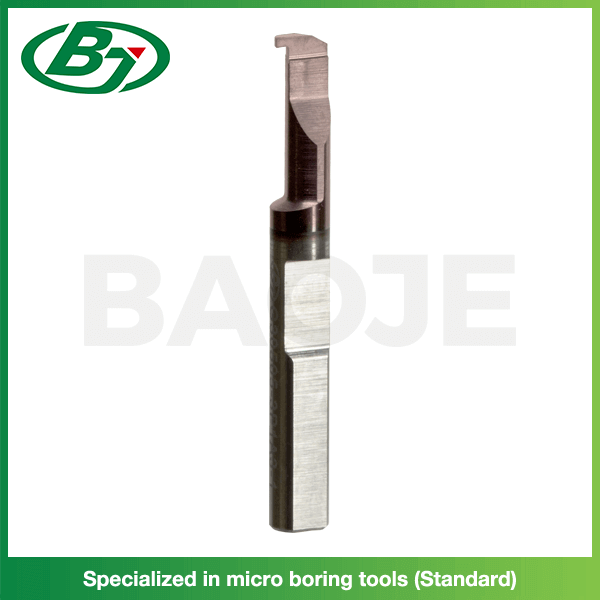

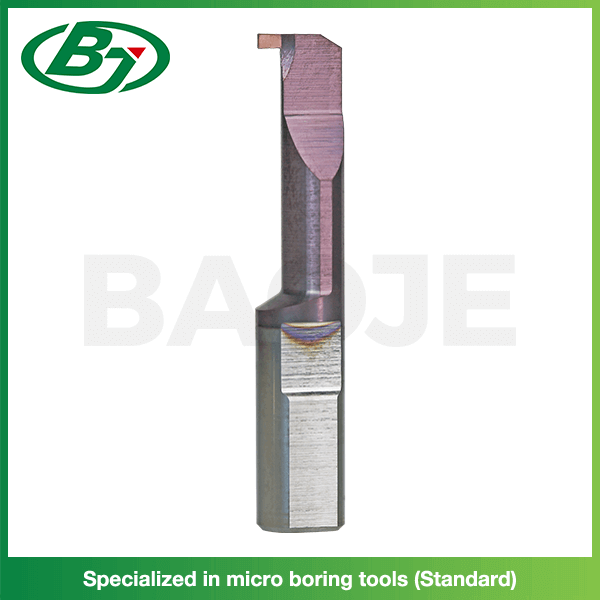

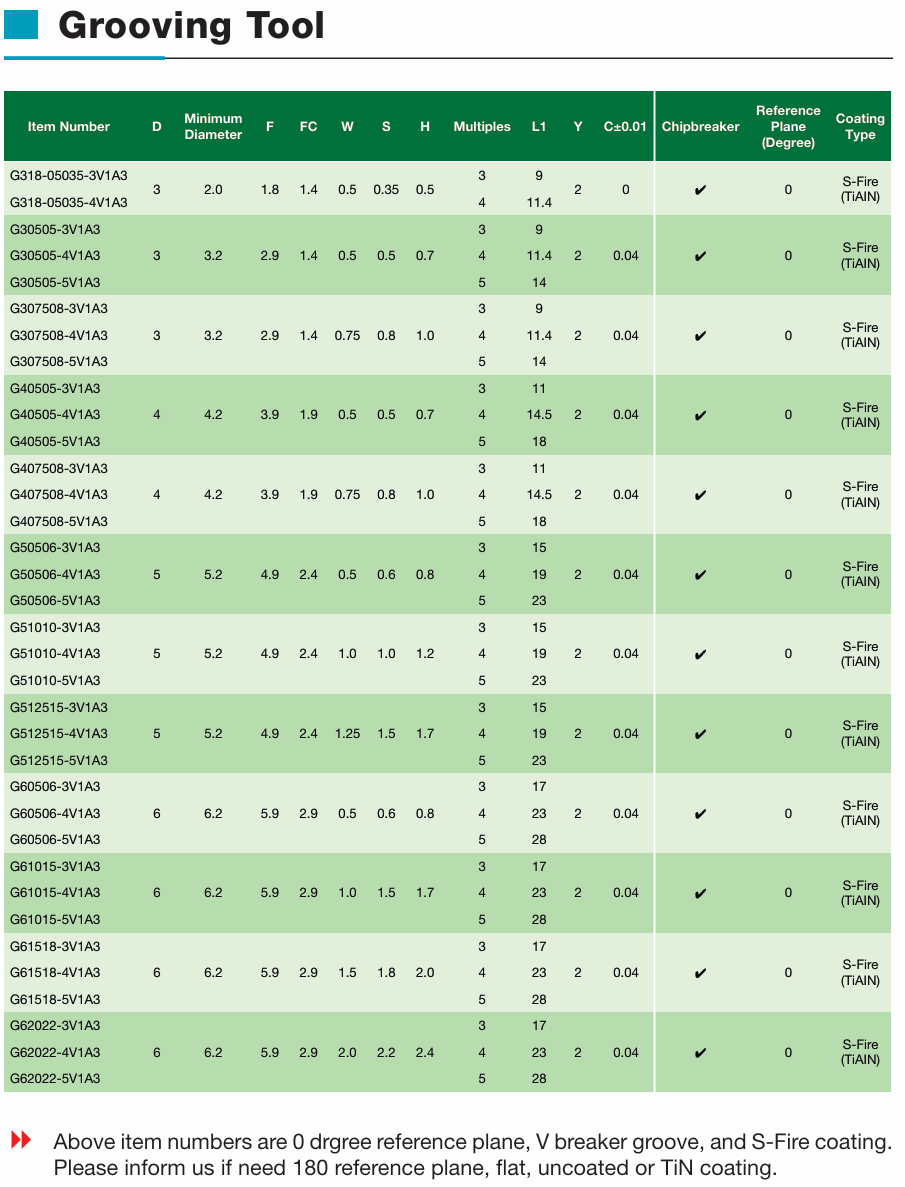

(G)Grooving

Specifications:

0.6mm~ 8mm. Tungsten carbide materials are imported from Europe and Japan.

Characteristics:

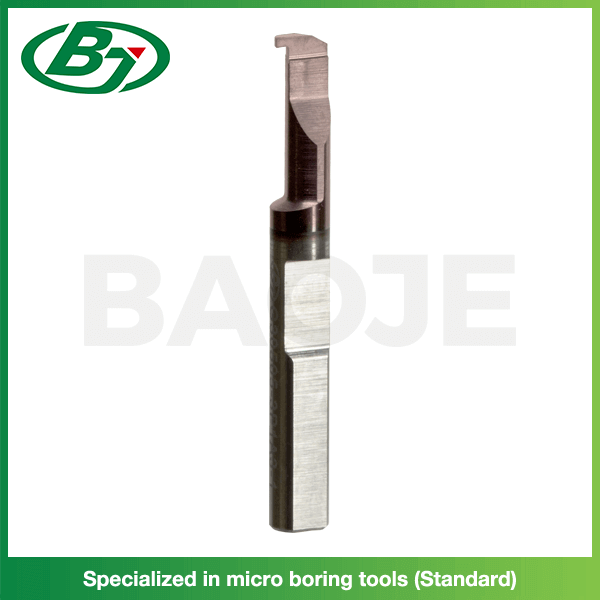

For Rough orprecision cutting use.

Notes:

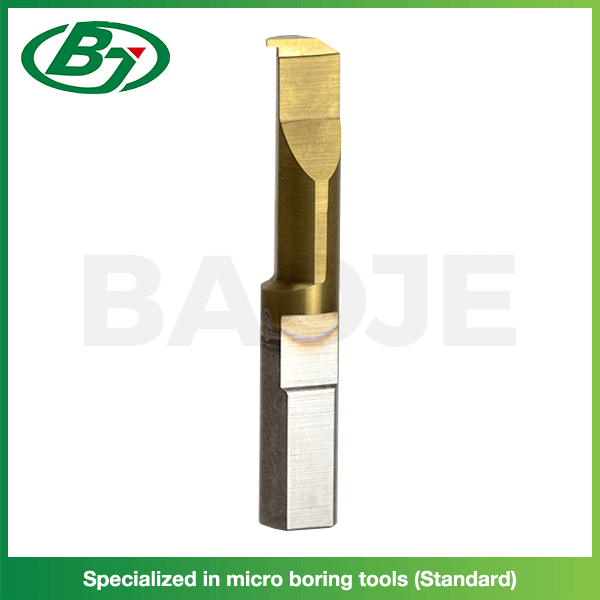

Coated by imported equipment.

Grooving Tool

Tungsten Carbide Inner-Hole Grooving Tool

Tungsten inner-hole grooving tool both front tip types are radius and chamfer will provide suitable type according to customer machining requirements.

Grooving tool will machine off more material during machining process, so if not properly designed might happen/occur the following situation:

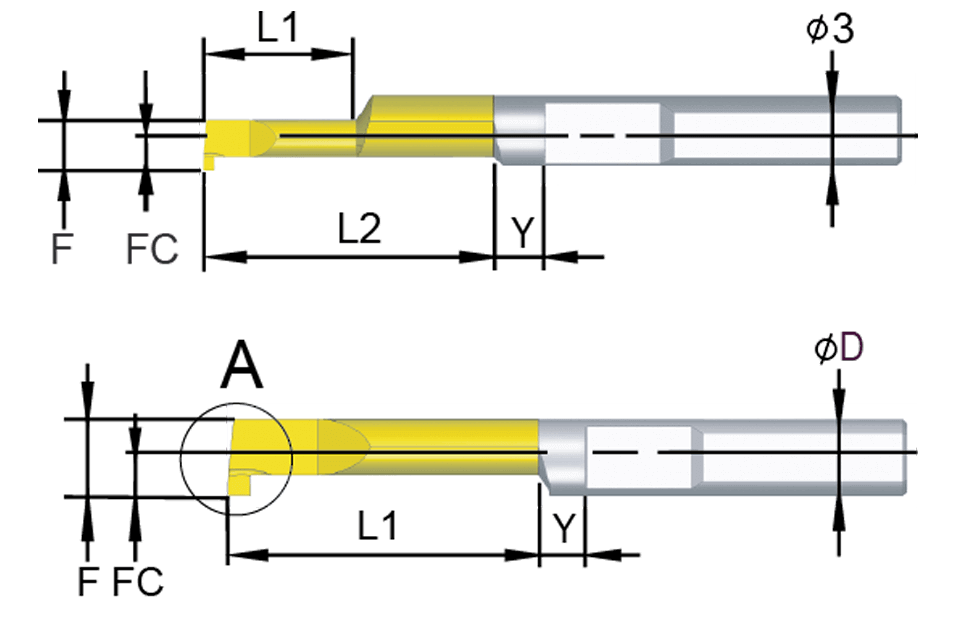

1.The tool tip to the tungsten carbide outside diameter length F is designed too small will cause broken tool during machining due to high machining torque applied to the tool tip.

2.If the grooving tool width designed too big that machines workpiece material too much will cause tool oscillating with obvious workpiece surface machining patterns.

3.If machining rpm is set too low, the groove tool tip will be easily worn out and decrease the grooving tool life.

Suggest using workpiece required groove width to choose suitable grooving tool width, if workpiece surface roughness is required, can grooving in two machining process, first machining process grooving the groove, second machining process grooving the groove second time and then machine the groove surface with machining programming.

If the groove surface roughness is not required and demanding machining capacity, can choose suitable grooving tool tip width to groove the groove in one machining process when workpiece material and groove width is appropriate.

Tungsten inner-hole grooving tool can perform grooving operation and also workpiece inner-hole finishing and roughing operations.

How to use Baoje Tungsten Inner-Hole Grooving Tool

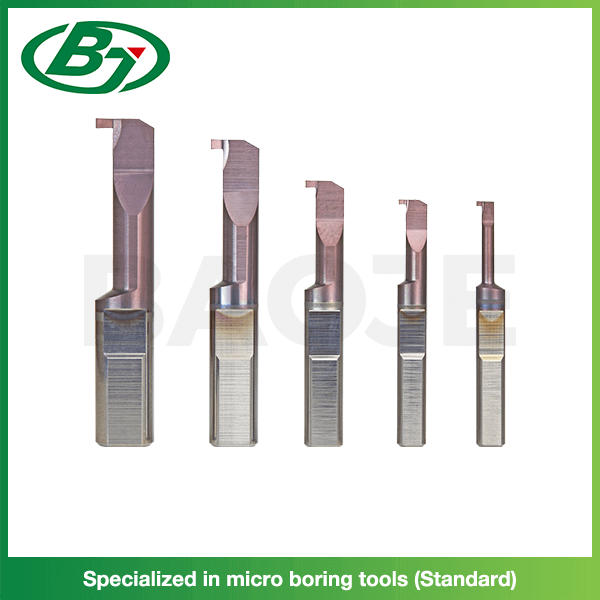

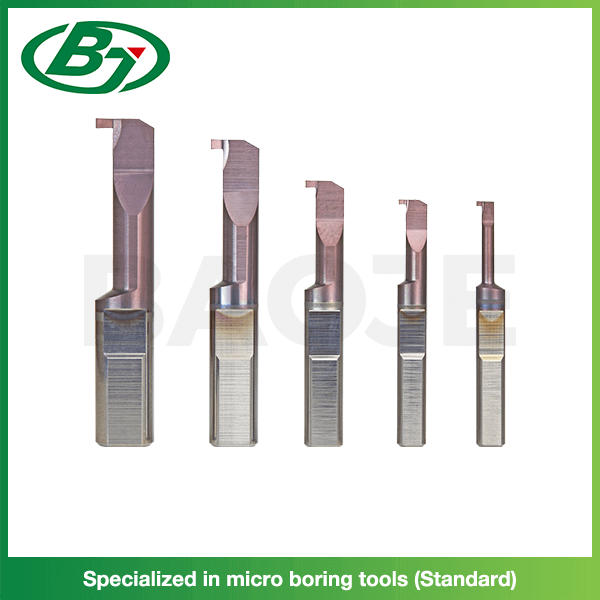

Baoje Tungsten Carbide inner-hole grooving tool specializes micro inner-hole machining, there are standard grooving tools and customized grooving tools, Baoje provides Tungsten Carbide bar in diameters 3, 4, 5, 6 and 8. And can design grooving tool according to customer required workpiece machining drawing.

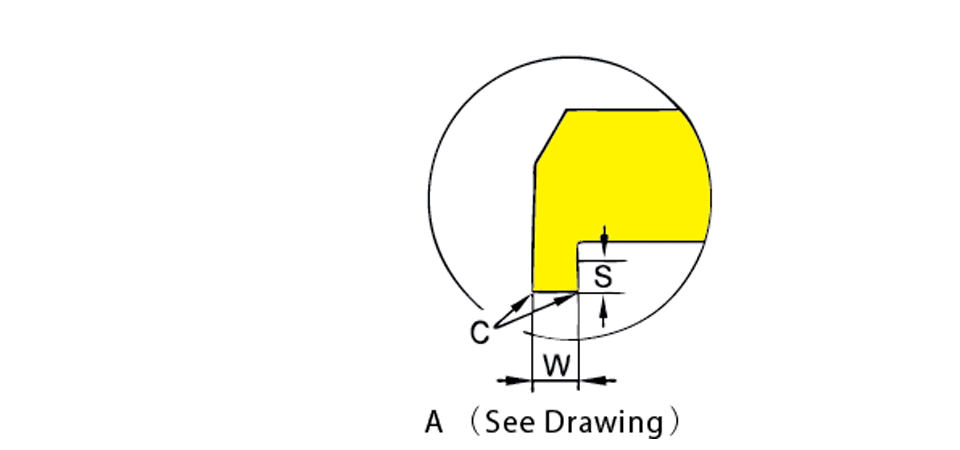

Per workpiece machining requirements, chamfer is commonly with C0.04 or radius of R0.05 / R0.01, Baoje can customize grooving tool with different specification, and also provide round nose grooving tool upon request.

Baoje customized inner-hole grooving tool according to customer machining requirement that include: surface roughness, machining capacity, workpiece machining drawing, workpiece material, machining methods and machining paths to design suitable inner-hole grooving tool.

We do customize the above tool every dimensions including F / FC / L1 / L2 / W / S / C / ΦD / Tip Radius, according to your requirement beside standard grooving tool.

Videos

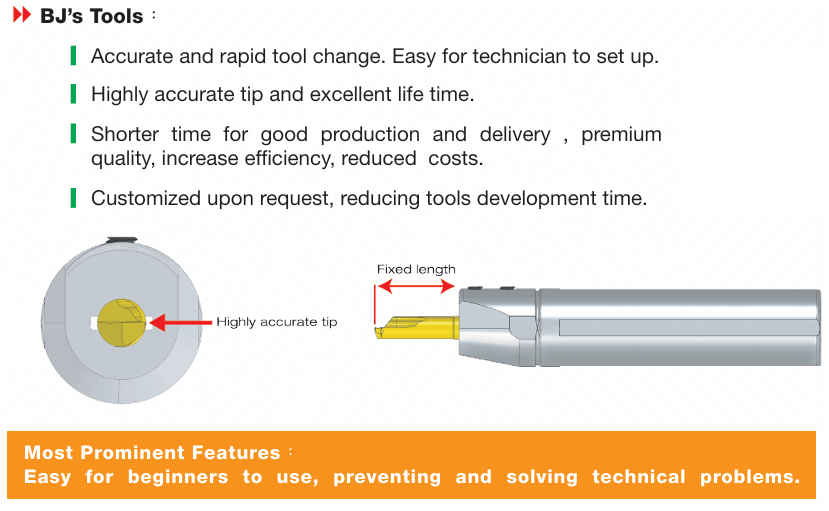

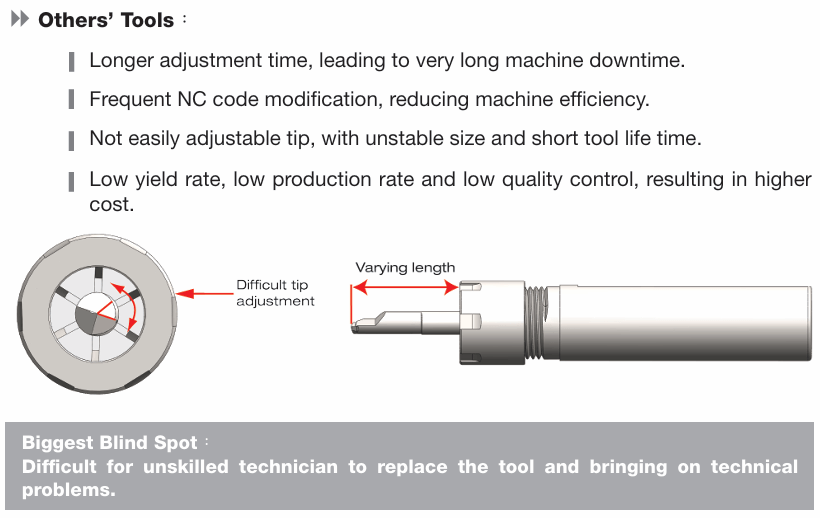

Superior techniques, premium quality adherence.

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.

Superior techniques, premium quality adherence.

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.