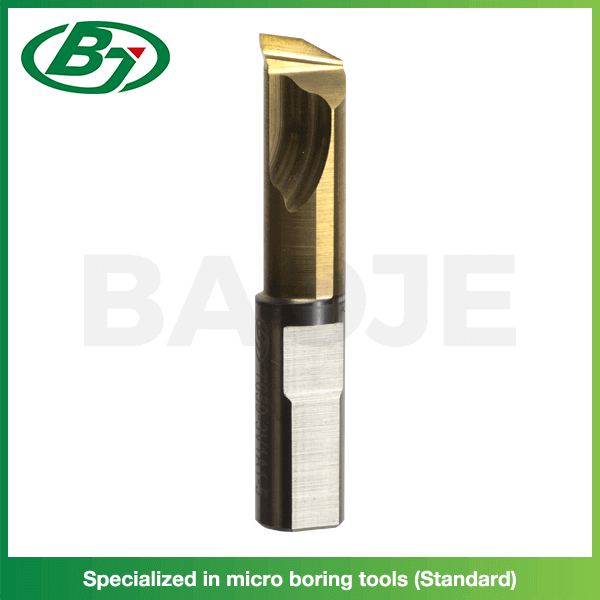

Tool type: 10° Turning Tool | Ø Shaft (d): 3mm | Length cutting edge (l1): 6mm | Length effective (l2): 8mm | Corner radius (R): 0.05mm | Coating: TiN | Point angles: 10° | Chip breaker: flat | Position of the clamping surface: 0° | Min. bore Ø: 2mm | Cutting Edge Ø (F): 1.8mm | Max. Turning length (xF): 3xF |

► 3~7 days delivery time

10° Turning Tool type T318-3P11

Description

Specifications

| Tool no. | T318-3P11 |

Feed Fz and cutting speed Vc

| P1 Steel < 500 N/mm² | 0.03-0.08 mm/min⁻¹ 60-120 m/min |

| P2 Steel 500-700 N/mm² | 0.03-0.08 mm/min⁻¹ 60-100 m/min |

| P3 Steel 600-800 N/mm² | 0.03-0.08 mm/min⁻¹ 70-120 m/min |

| M2 Stainless steel < 750 N/mm² | 0.03-0.08 mm/min⁻¹ 50-80 m/min |

| M3 Stainless steel < 850 N/mm² | 0.03-0.08 mm/min⁻¹ 50-80 m/min |

| M4 Stainless steel < 950 N/mm² | 0.03-0.08 mm/min⁻¹ 50-80 m/min |

| N1 Aluminium alloys ≤ 12% Si | 0.03-0.08 mm/min⁻¹ 100-150 m/min |

| N2 Aluminium alloys > 12% Si | 0.03-0.08 mm/min⁻¹ 100-150 m/min |

| N4 Bronze and brass | 0.03-0.08 mm/min⁻¹ 100-150 m/min |

| H1 Hardened steel 35-45 HRC | 0.03-0.08 mm/min⁻¹ 50-80 m/min |

| H3 Hardened steel 52-62 HRC | 0.03-0.08 mm/min⁻¹ 50-80 m/min |

Technical data

| Tool type | 10° Turning Tool |

| Ø Shaft (d) | 3mm |

| Length cutting edge (l1) | 6mm |

| Length effective (l2) | 8mm |

| Corner radius (R) | 0.05mm |

| Coating | TiN |

| Point angles | 10° |

| Chip breaker | flat |

| Min. bore Ø | 2.0mm |

| Cutting Edge Ø (F) | 1.8mm |

| Offset from tool center (FC) | 1.4mm |

| Lenght (Y) | 3mm |

| Max. Turning length (xF) | 3xF |