The Characteristics of CNC Turning Tools

2018-07-26

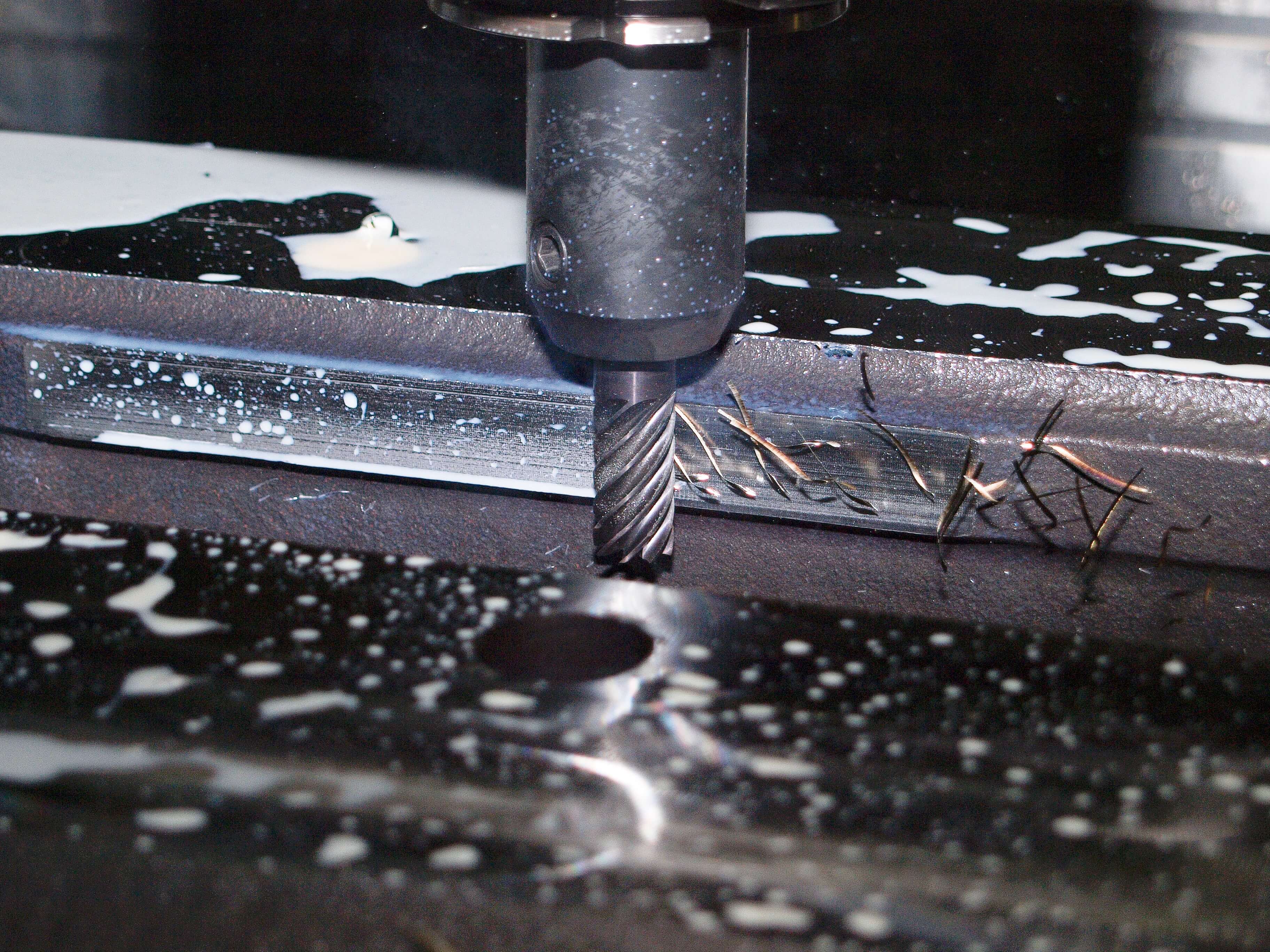

The tools must frequently be changed in addition to maintained in order to create quality solutions. You might need to use a number of different cutting tools, based on the size and variety of material you’re producing. The cutting tool must be kept at work until you have the depth and dimension that you wanted. CNC (computer numerical control) tools such as lathes have turned into a crucial part of manufacturing in a full selection of industries.

In a closed loop system, the control is mindful of the true place of the axis in any way times. The CNC control may use the tips location to set it in the proper spot linked to the zero point. No other control provides the degree of flexibility you will experience with the Hurco control. You can have entire charge of the machine using the computer that operates it.

Want to Know More About CNC Turning Tools?

If you’re looking to get some CNC work done, take a look at our Services” tab on the home website for the overall info about what we offer. The load time can be contingent on the size, weight, and intricacy of the workpiece, and the kind of fixture. Now is the time to enumerate the benefits that companies can reap once hiring machines that could offer the very best turning solution in the business. Finally, the tool replacement time is an immediate effect of the range of tool replacements that is discussed about the tooling price. Tool life is a significant characteristic that’s considered when choosing a tool, as it greatly impacts the manufacturing expenses.

CNC controls enable you to simulate the program. The CNC turning machine is simply the machine you need if you’re into work that involves heavy machinery and demands lots of precision. The CNC turning centers are controlled by a really advanced computer that provides you the accurate result that you want. Operating a CNC lathe can be achieved with a keen awareness of detail by making certain that all conventional procedures are followed thoroughly. The bigger lathes are floor mounted and may call for exclusive transportation if they have to be moved. Turret lathes and distinctive purpose lathes are usually utilized in production or job shops for mass creation or specialized parts, while basic engine lathes are typically used for any kind of lathe work. Climb milling assures the part isn’t going to slip whenever you’re cutting.

With a CNC lathe, it is simple to create complex parts that would be rather tough to machine on a manual lathe. Lighter-duty machines frequently do not hold their tolerances together with more rigidly constructed machines. At precisely the same time, such machines help to acquire proficiency utilizing different sets of materials to do many tasks or activities at a 1 go.

A number of our machines are equipped with different kinds of automation and tool magazine configurations. The boring machines have completely altered the manner construction occurs today. Turning machines may also be categorized by the kind of control that is supplied. Turning machines, typically called lathes, can be seen in a range of sizes and designs.

BAOJE Cutting Tool Series:

https://www.baojetools.com/cutting-tools/

BAOJE Customized Tools Display

https://www.baojetools.com/case/

Extended reading:How To Train CNC Lathe Technicians

Extended reading:Analysis of CNC Lathe Technician Shortage

Other News

Superior techniques, premium quality adherence.

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.

Superior techniques, premium quality adherence.

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.